Predictive Shipment Intelligence

See late shipments before they disrupt production and prevent costly line stoppages.

See late shipments before they disrupt production and prevent costly line stoppages.

Late ASNs shut down production lines, costing $20K–$50K per hour in lost output

Planners react to delays too late, scrambling for expensive expedited shipments

Excess inventory tied up as safety stock because suppliers can't be trusted

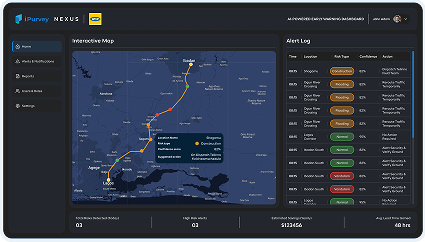

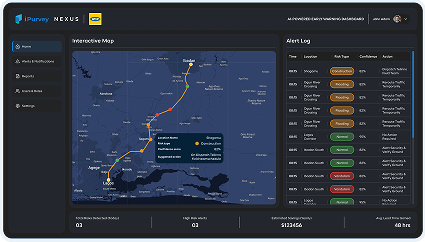

Monitor ASNs, carrier tracking, and port congestion data across all inbound suppliers

AI identifies which shipments will arrive late based on carrier performance and disruption patterns

Automated alerts sent to planners 3–5 days early with alternative sourcing or schedule recommendations

Zero line stoppages, 50% fewer expedited shipments, 20% reduction in safety stock

We're transparent about what's live, what depends on data, and what's planned.

Inbound IQ predictions depend on Advanced Ship Notice (ASN) data quality from suppliers and ERP integration depth. Suppliers without EDI (Electronic Data Interchange) capabilities provide less accurate shipment visibility.

Delay predictions improve with historical data. New implementations require 2–3 months of operation to establish baseline performance patterns for each supplier and route.

From 4–6 per month

Saving $300K+ annually

Freeing up working capital

No more unplanned stoppages, smoother manufacturing flow, fewer expedited shipments.

Join manufacturers using Inbound IQ to predict ASN delays and keep production flowing

Free consultation • ERP integration included • Launch in weeks

Discover Inbound IQ